Who more and who less has had a few days to rest and take the opportunity to take a trip. In my case I was able to visit some towns in the northern part of Spain that I still had pending and discover new ones. When we plan a trip, it is clear that we think about the destination but also about how to get there. We look at where we can stop to sleep, if there are nice places to visit on the way, etc. The trip is not only the destination, it is also the way. Hasn’t it ever happened to you that you have discovered on the way some place more beautiful than the destination itself? Haven’t you sometimes enjoyed more on the way than when you arrived?

Let’s try to apply this reasoning to business processes. I do not mean that we stay in other departments in the company visiting, but to understand the steps performed and the value obtained in each of them, to see if other partial benefits can be obtained before reaching the final benefit; before arriving at the destination. Maximize the value chain.

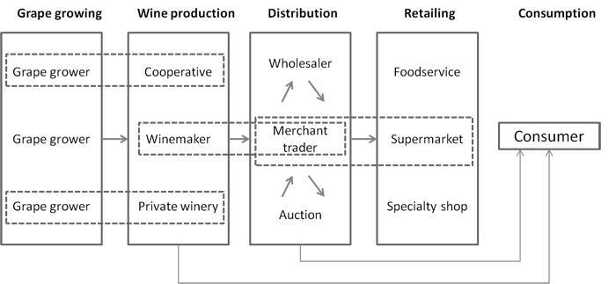

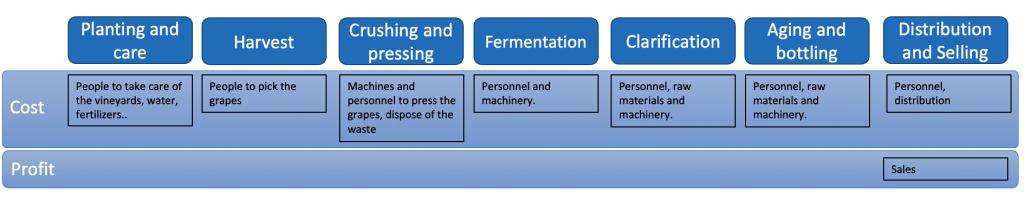

To help me do this, I am going to use a simile with wine. In a very schematic way, in order to sell wine, we have grapes that are pressed, we obtain the juice that is fermented, we obtain wine that we put in bottles and then we sell. We can see this process as a series of steps with associated costs (purchase of land, irrigation, fertilizers, labor, machinery, marketing, distribution, etc.) and at the end of which we obtain the profit, the sale of the bottle. We have reached our destination. In Figure 2 we can see a diagram of some of the steps in the process (it is only an example, I am not an expert winemaker). Seen in this way, it seems that from the moment we buy the land and plant the vines, everything is expenses until we obtain the profit from the sale of the bottled wine, at the very end of the process.

But let’s take a closer look at the value stream steps: Can we make sales before we have the finished product and maximize the benefit of these intermediate steps?

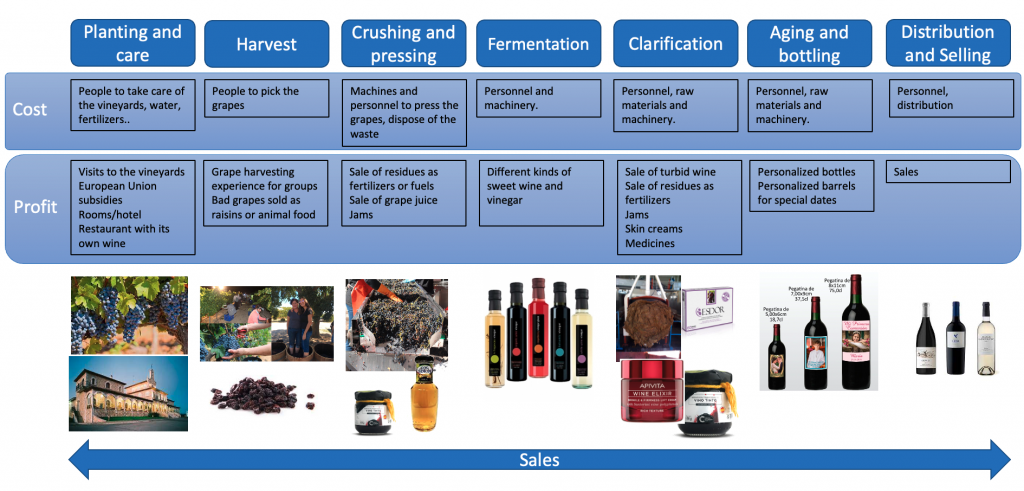

It is possible that if we are asked to improve the process, the first thing that comes to mind is how to reduce costs and time. If we also think about how to get the maximum benefit from the process at each step (even taking advantage of waste), we open the possibility of finding new revenues and business models.

Let’s see:

- Planting and care: We can make guided tours through the vineyards, have rooms for conventions and show the vines as experience, have a hotel/restaurant where we can also sell the wine…

- Harvest: Experiences of stay in the hotel and harvesting, sale of grapes in bad condition for animal food or creation of raisins, …

- Pressing: Sale of grape juice (the juice before fermentation), use of the residues as own fertilizers or for sale, …

- Fermentation: Creation of sweet wines, low alcohol wines, vinegars,…

- Clarification: Use of the residues to make creams, medicines, fertilizers, jams,…

- Bottling: Sale of numbered bottles, personalized bottles for special events,…

- Sales: Selling in the plantation itself or in the hotel-restaurant, instead of only in supermarkets, on the Internet…

In this example, we can see that during the process (the trip), it is possible to enjoy every step of the way by obtaining benefits without needing to wait to get to the end. As in everything, there are some of these income streams that need less investment than others and others that have less risk, but the important thing is to squeeze the process to get the most value out of it.

It is said that a famous Spanish company dedicated to the production of sausages found that after the preparation of the product, there were some leftovers in the hoppers that were no longer useful for making sausages. They were leftovers that were disposed of. In an attempt to minimize the leftovers, it was proposed to make a profit from them, possibly selling them as an ingredient for certain feedstuffs. However, they opted for another much more profitable option, using it as a pizza topping. Thus, this company began to use the surplus from its main product line (sausages) to make a secondary product (pizzas). Today, pizzas have become one of its main products, and are even sold as a private label in some supermarkets. During the process improvement to reduce costs, they found a new and succulent business.

When we talk about process improvement, it is not only about cost reduction, it is about improving the entire value chain.